|

|||

|

|

|||

|

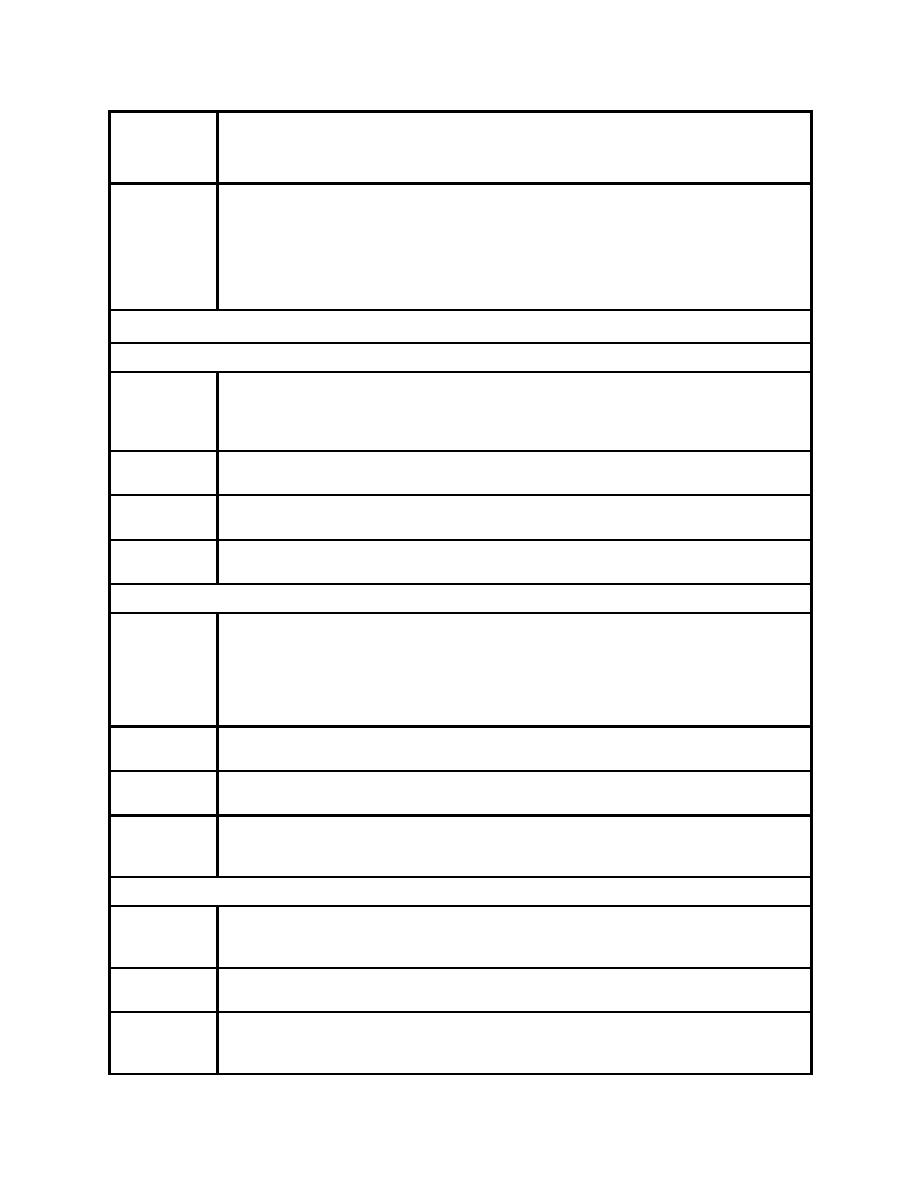

Page Title:

Develop and Implement Hazard Controls |

|

||

| ||||||||||

|

|  DOE-STD-1120-2005/Vol. 2

Action

ISMS GUIDELINES FOR FACILITY DISPOSITION AND

Completed

ENVIRONMENTAL RESTORATION

(Yes/No)

Workers, first-line supervisors, and safety personnel are involved in walkdowns of the work on

an as-needed basis to review the steps associated with a task and to identify the hazards

associated with the workplace and the chosen work methods.

DEVELOP AND IMPLEMENT HAZARD CONTROLS

Worker Safety Controls

ES&H requirements/standards, including controls stemming from baseline documentation and

commitments, are effectively translated into work procedures and instructions. The strategy for

establishing safety controls for facility disposition workers is consistent with the hierarchy

specified in DOE O 440.1.

Operational safety commitments for each work method are clearly identified and reflected in the

task work plan or package.

Personnel qualifications and training requirements are derived from the hazard analyses and are

clearly specified in work packages.

Task sequences, prerequisites, and hold points related to ES&H are documented in the work

package.

Facility Safety Controls

An evaluation is made based on the hazard analysis results and planning data for the facility

safety controls needed during disposition activities. Existing safety controls may be retired

during the course of a disposition activity when the hazardous condition being controlled is no

longer present, the hazardous substances are no longer present, the substance's form has

changed to a less dispersible form, or the quantity of substance has been reduced to a level

where the consequences of potential exposure no longer present a concern.

Establishment of safety controls considers uncertainties in material inventories or hazardous

conditions and uses conservative assumptions in designating controls.

Hold points are established for conducting characterization or additional analysis to determine if

the condition warrants establishing or changing a safety control.

Assumptions pertaining to location, forms, or quantities of hazardous substances are sufficiently

conservative to ensure that safety is not compromised before or during characterization

activities.

Safety Basis Documentation

Safety Basis documentation clearly reflects disposition work scope and anticipated hazards and

their associated controls, including safety equipment functional and performance requirements,

as well as administrative controls and programmatic commitments.

Approval of the safety basis documents has been secured consistent with designated Program

Secretarial Officer's delegation of authority protocols as well as site protocols.

Information needed to be included in worker training related to controls, commitments, or

operating limits has been clearly documented and transferred to the person or organization

responsible for creating the training module(s).

C-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |