|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-HDBK-3010-94

7.0 Application Examples; Dissolving Operations Examples

7.3.2. Oxide Dissolution

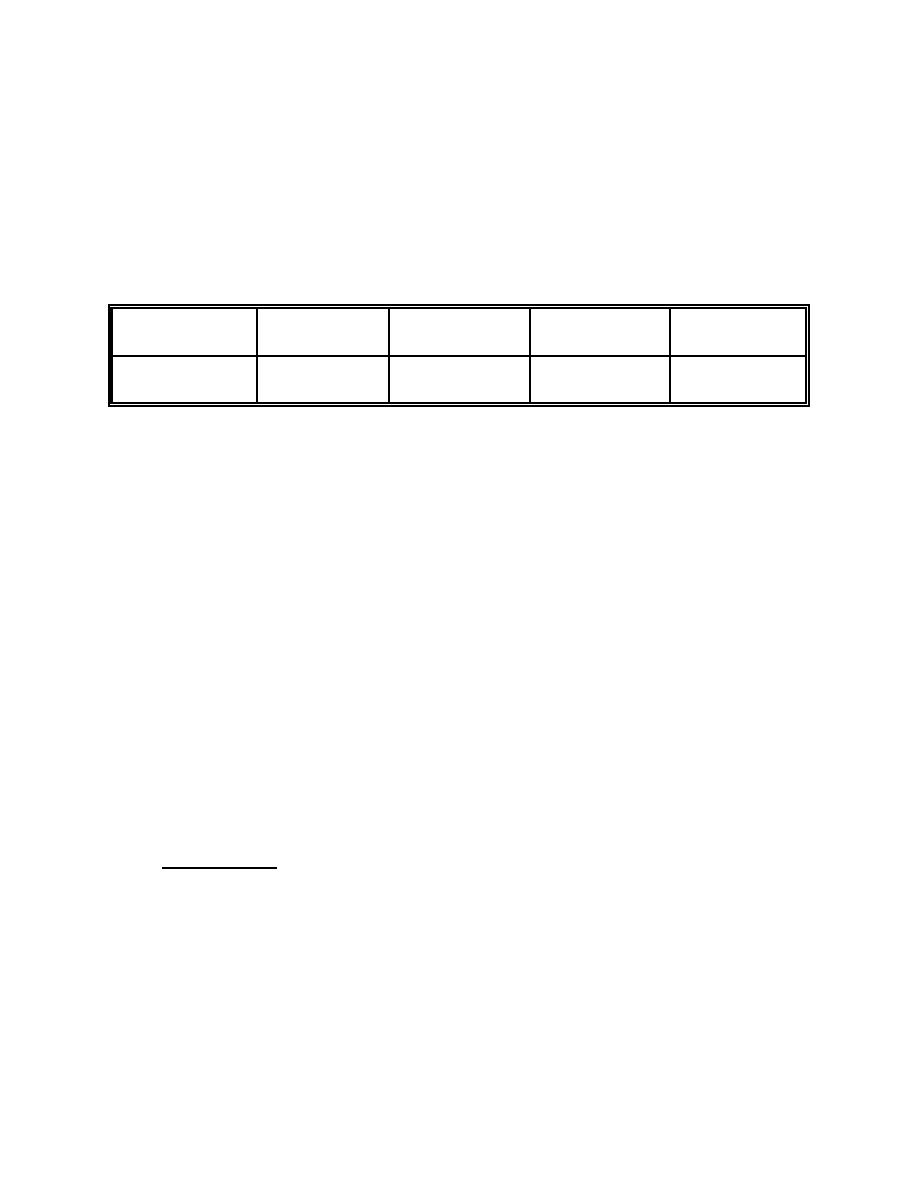

Release topics explored in this example are listed in Table 7-4:

Table 7-4. Oxide Dissolution Example Topics

Liquid

Metal

Powder

Surface

Criticality

- Thermal stress

- N/A

- None

- None

- Solution

- Free-fall spill

7.3.2.1

Hazard Summary

This activity receives plutonium oxide powder from the feed preparation operation via a

conveyor. This material is fed into a nitric acid dissolver, after which only liquid materials

are handled. 64% nitric acid is fed into the dissolver by a dedicated feed tank on the second

floor, and 35% nitric acid is added to subsequent vessels by a common feed tank servicing

all three dissolving line gloveboxes. Process and instrument air and nitrogen are fed into the

glovebox by pressurized sources ranging from 0.1 to 0.55 MPag (15 to 80 psig). The

dissolver is heated by 0.21 MPag steam (35 psig). Transfers between tanks in the glovebox

are by vacuum eduction. There are no highly energetic reactions associated with the

dissolution process itself. Radiolysis of water can produce small amounts of hydrogen over

long periods of time, but the vessels are supplied with an ever-open vent to the vessel vent

system and a continuous small air purge while in use.

7.3.2.2

Release Estimation

The potential energetic phenomena are a liquid spill, boiling liquid due to dissolver

temperature control malfunction, and a liquid criticality. There is no clear mechanism for a

large room fire, and one is not examined because its only effect would be liquid boiling.

A. Liquid Spill. The dissolution process is a batch operation. The maximum feed

allowed in any one batch is 1322 g as plutonium (1500 g PuO2). A spill can occur

from a piping or vessel leak due to corrosion, or inadvertent damage from an activity

such as maintenance or an unrelated accident. If the leak in a line is small, or a leak

in a vessel is above the vessel bottom, not all of the material would be spilled. For

the sake of simplicity, a leak large enough and situated so as to allow all of the liquid

to drain from confinement is postulated (i.e., DR = 1.0). At a vessel low point, the

maximum possible fall height is ~ 0.3 m (1 ft), while a leak from a transfer line could

produce a fall of ~ 1.2 m (4 ft).

Page 7-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |