|

|||

|

|

|||

|

Page Title:

Appendix I. Glovebox Window Material Comparison |

|

||

| ||||||||||

|

|  DOE-STD-1066-99

Appendix I. Glovebox Window Material Comparison

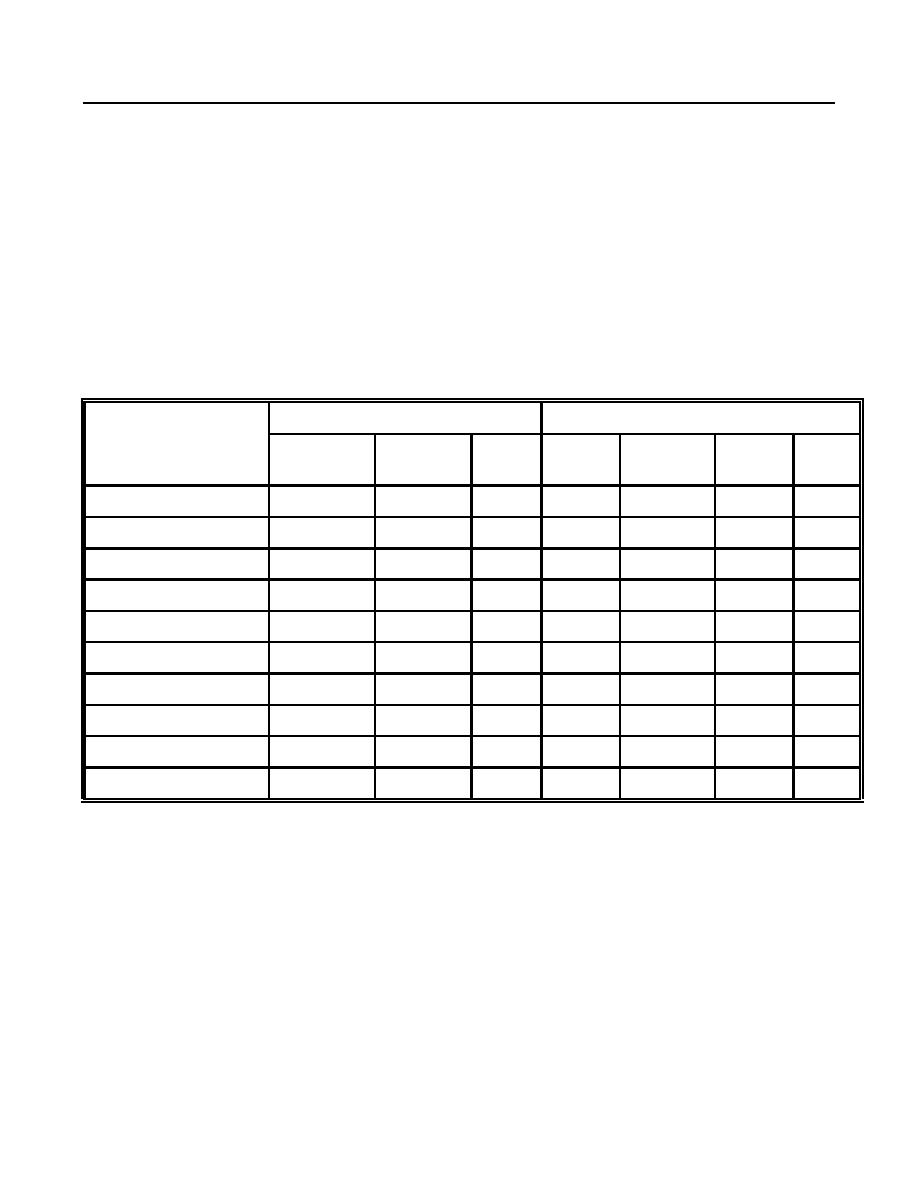

Windows can be the most challenging part of glovebox designs. It is often hard to find a material that

satisfies operational requirements and the fire protection and atmosphere compatibility criteria. This chart

was developed by Factory Mutual Research Corporation with information from other sources (a few

changes were made to the chart such as trade names were relabeled using the material's chemical

name). Materials were rated in terms of how well they performed in the areas listed in the left column;

materials were judged to be excellent, good, fair, medium, poor, or to have no capability for that criterion.

A newer material (developed after these tests), that may be useful as a window material, is fire-rated

glass. Note that these are for information purposes only. Window design requirements are provided in

Section 4 of this standard.

Testing Areas

Plastics

PMMA1

ADC2

P.C.3

PMMA

Laminated

Tempere

Wired

SE-3

d

Optics

exc.

exc.

fair

exc.

exc.

exc.

good

Combustibility

exc.

none

none

poor

fair

fair

fair

Heat Resistance

fair

good

exc.

fair

fair

fair

fair

Impact Resistance

fair

good

good

good

good

good

exc.

exc.4

exc.4

exc.4

Chemical Resistance

good

fair

good

good

exc.5

exc.5

exc.5

--

--

--

--

Abrasion Resistance

exc.

exc.

exc.

fair

fair

good

poor

Flexibility

poor

fair

poor

exc.

good

fair

good

Workability

poor

poor

poor

exc.

good

good

good

Cost

med.

med.

med.

low

med.

high

high

Notes:

1

Polymethylmethacrylate

2

Allyldiglycalcarbonate

3

Polycarbonate

4

Except to hydrofluoric acid

5

If non-browning glass (cerium added)

Wired glass is strongly recommended for all windows, where visibility through the wire layer is tolerable.

Otherwise, laminated safety glass (from sheet or plate stock) is recommended.

Where hydrofluoric acid exposure is serious, where workability of the window material is important, or

where the fire hazard is considered not serious, a polycarbonate is recommended.

I-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |