|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-STD-1128-98

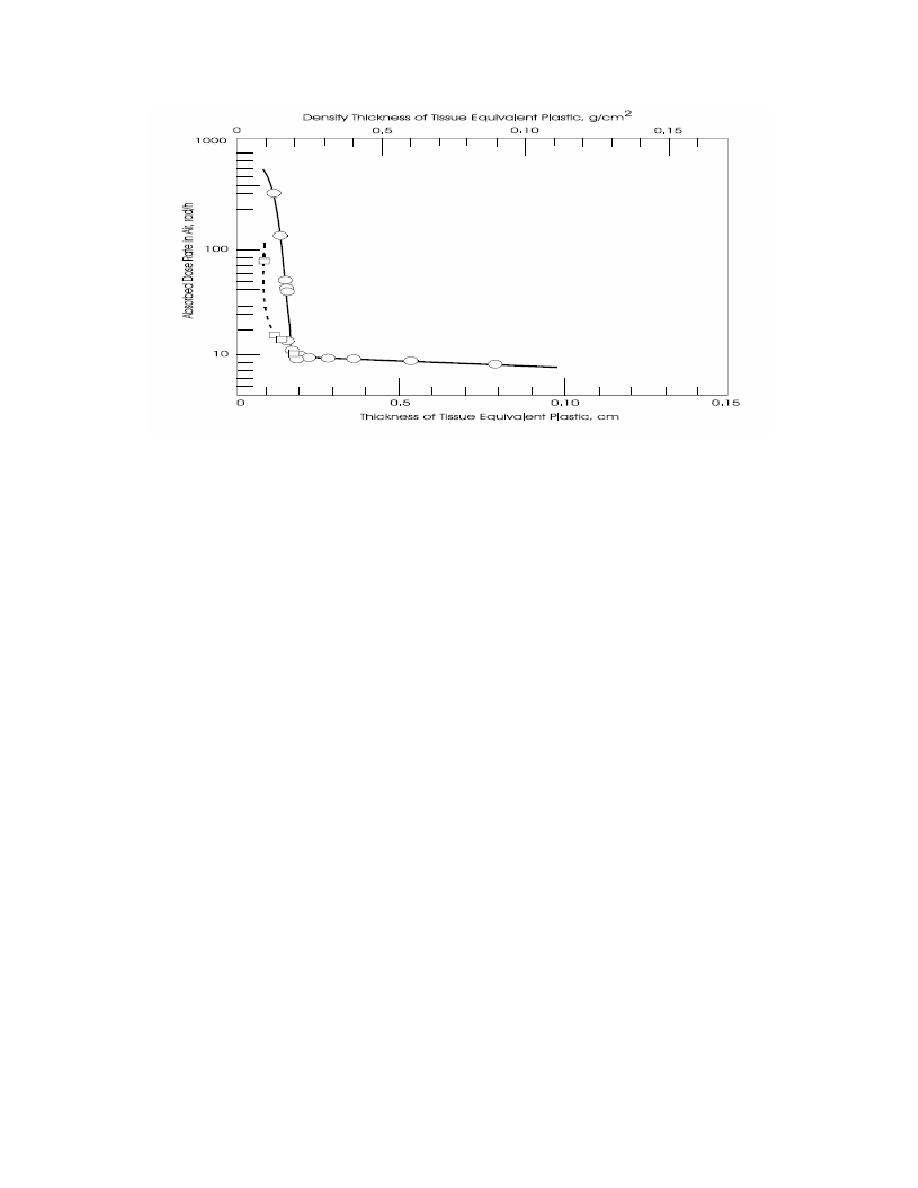

Figure 6.1.

Absorbed Surface Dose Rate from Plutonium Dioxide as Measured with

an Extrapolation Chamber

Figure 6.1 shows the dose rate as a function of tissue equivalent plastic absorber

thickness, as measured by an extrapolation chamber in contact with a 3-in.-

diameter plutonium dioxide source coated with a very thin layer of beryllium for

contamination control. The plutonium was compressed to about 80% of its

theoretical density and vitrified by a Dynapack process in which powder was

compressed into a glassy solid by extreme pressure and heat evolved during the

compression process. The plutonium oxide disk is mechanically stable and

produces little smearable contamination. Even minute layers of tissue equivalent

plastic reduce the dose rate significantly, as shown in Figure 6.1.

6.2.2

Gamma Doses

There can be substantial gamma doses involved in the processing and handling of

plutonium, particularly in glove-box operations involving plutonium dioxide

powders. Plutonium emits very few highly penetrating gamma rays; most of the

radiations are L X-rays, which are very easily shielded. Because most of the

photons emitted by plutonium are of low energy, plutonium sources are

"infinitely thick" relative to their photon radiations, i.e., an additional thickness

of plutonium does not appreciably increase the photon dose rate. A plutonium

metal source of about 1-mm thickness or a plutonium oxide source about 6-mm-

thick is "infinitely thick" due to self-shielding.

6-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |