|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-STD-1128-98

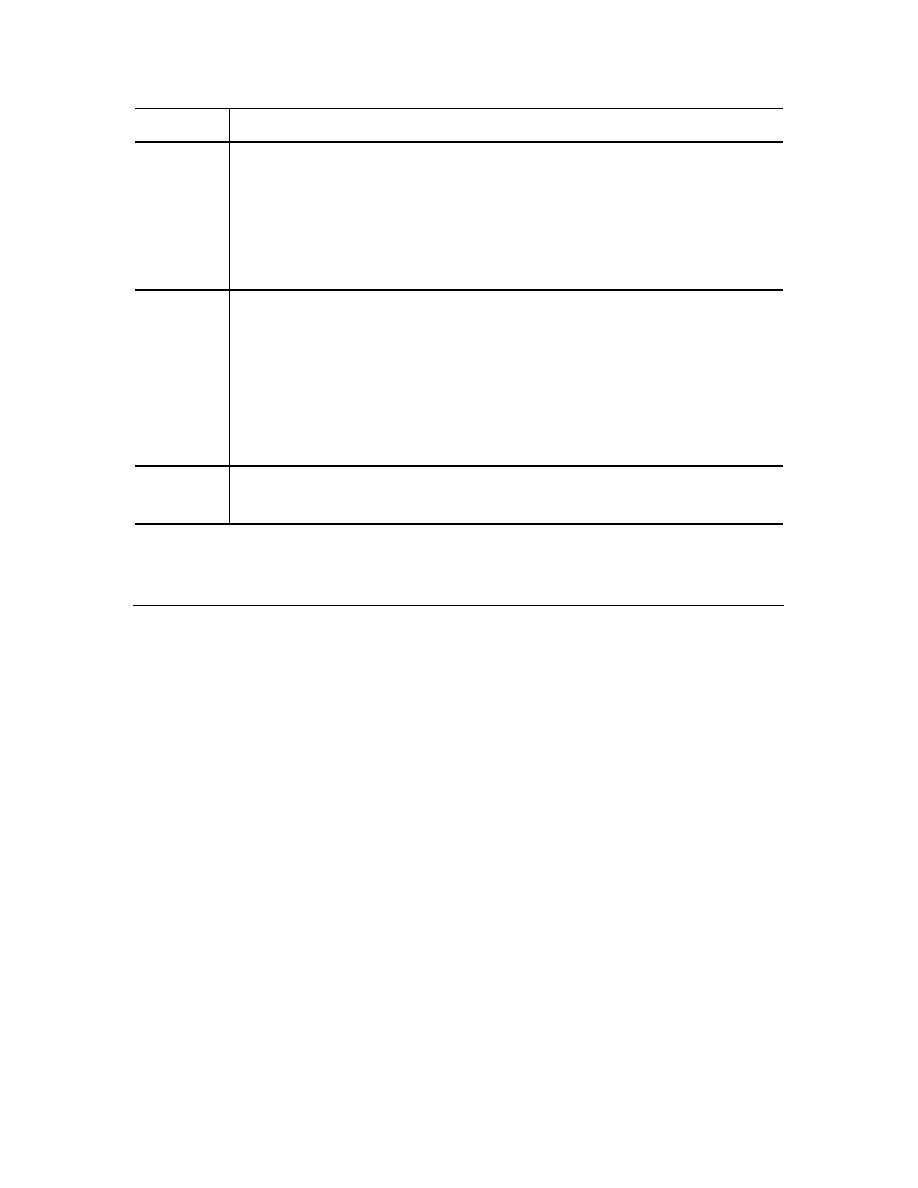

Table 8.3 (cont'd)

10.

Impure oxide from sources other than metal should be thermally stabilized at

1000100C for at least an hour, or placed in a combination of a slightly lower

temperature (-850C) for longer heating time to result in the lowest loss on

ignition (LOI) practicable with existing equipment. This ensures complete

conversion of substoichiometric material and aids small-particle

coalescence, which diminishes dispersal risk.

11.

Because plutonium oxide has greater potential for dispersion in severe accidents,

it should have priority over metal for storage in structurally robust vaults. Metal

should be characterized to ensure that it has not converted to oxide while in

storage. Stored plutonium will have an increasing radiation level because of the

build-up of 241Am. Therefore, characterization of metal should be done as soon

as possible and should make full use of small-sample statistical methods to

minimize worker exposure. The results of characterization should be integrated

with a site's surveillance plan, as well.

12.

Quality assurance measures, labeling, and material characterization are essential.

Material and storage packaging specifics should be thoroughly documented.

(a) A higher oxidation rate may occur if the contained metal exhibits a high surface-area configuration, such as

sheet or foil. The maximum annual increase for normal (uncatalyzed) oxidation of a given metal geometry can

be calculated using a reaction rate of 3 x 10-7 g oxygen/cm2-minute measured for alpha-phase plutonium under

moist conditions at 50C.

8-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |