|

|||

|

|

|||

|

Page Title:

Calcination and Hydrofluorination |

|

||

| ||||||||||

|

|  DOE-HDBK-3010-94

7.0 Application Examples; Dry Processing Line Example

developing a clear checklist for valve positions at each step of the process, providing clear

direction or controls to ensure the vent valves remain open, and requiring experienced

supervision at all times while operating. If it was necessary to operate the system for the

long term, consideration would have to be given to issues such as removing the heat

exchanger system, possibly removing or caution tagging the isolation valves on the vent

lines, formally upgrading procedures, installing elevated piping legs for drain prevention, and

examining use of different resins to change loading patterns, optimize new process conditions

or possibly even preclude the phenomena from occurring. In short, a serious effort to regain

control of the process configuration for principal safety concerns would be necessary. While

the example operation is admittedly flawed to an extreme level, the errors included are based

on actual industrial experiences. An effective hazard analysis process, not estimation of an

initial source term, is the most productive vehicle for coming to grips with such issues.

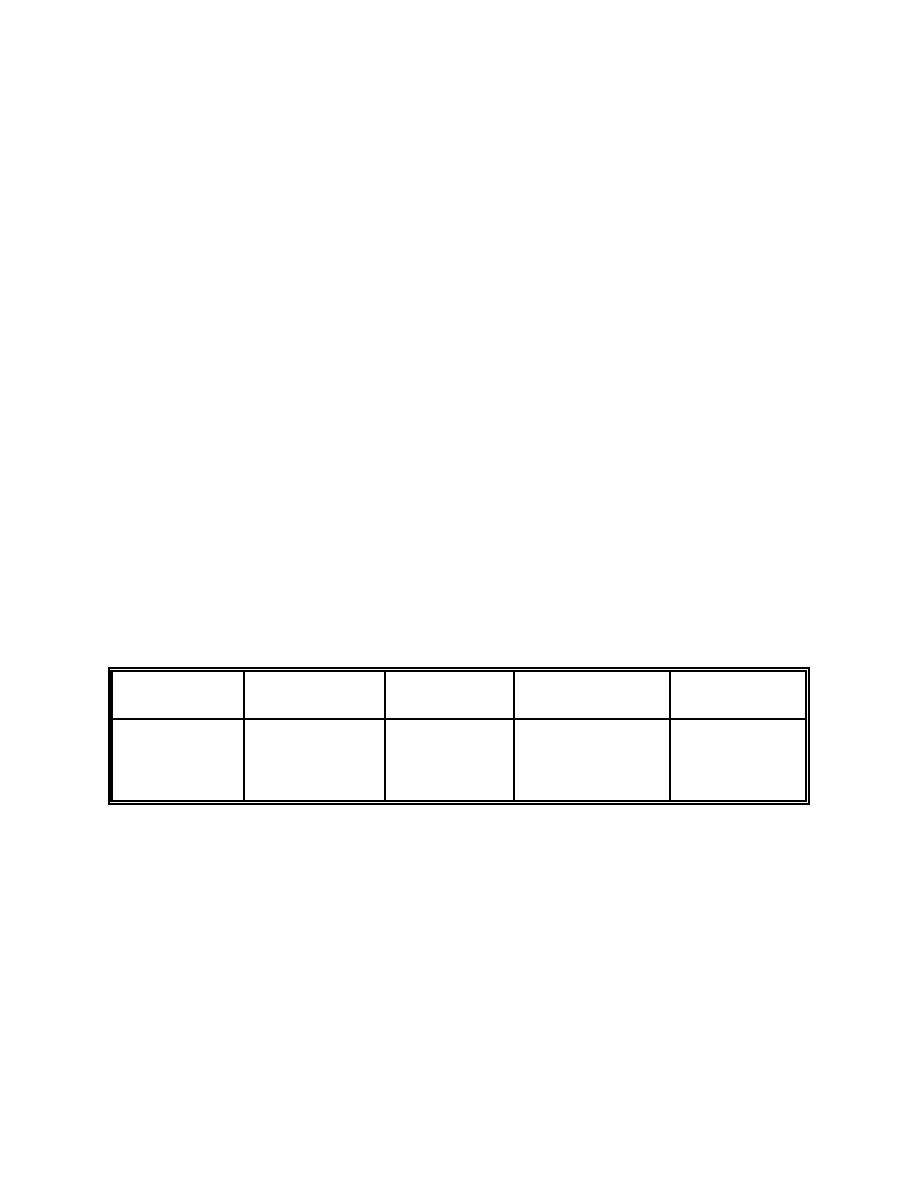

7.3.7 Calcination and Hydrofluorination

In the interests of brevity, the plutonium peroxide and evaporation operations are not

examined because they do not involve phenomenological concerns not already dealt with in

previous operations. The calcination and hydrofluorination operations are combined because

they operate in series and the main phenomenological concern for each is the same. Release

topics explored in this example are listed in Table 7-10.

Table 7-10. Calcination and Hydrofluorination Example Topics

Liquid

Metal

Powder

Surface

Criticality

- None

- N/A

- Thermal

- Thermal stress of

- None

stress

contaminated

cellulosics and

plastics

7.3.7.1

Hazard Summary

The calciner glovebox, part of the "dry" line, receives plastic jugs containing plutonium

peroxide precipitate from the "wet" line. These jugs are temporarily stored while awaiting

feed to the calciner. Material first goes through a low-temperature drying cycle in a small

box drying unit and is then placed in the calciner hopper, where a screw auger feeds it

through the calciner and the material is converted to plutonium oxide at elevated

temperatures (~ 370 oC). The output of the calciner enters a critically safe lag storage

hopper. Another screw auger then feeds this material to the hydrofluorinator, where a

counter-current flow of hydrogen fluoride reacts with the oxide to generate plutonium

Page 7-48

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |