|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-HDBK-3010-94

7.0 Application Examples; Dissolving Operations Examples

and momentary reverse pressurization of the glovebox can occur. However, the

actual pressure generated in the dissolver is not large, and is certainly below the

0.345 MPag (50 psig) threshold this handbook defines for differentiating a high-

pressure release from a low-pressure release. The ARF and RF for depressurization

of liquid containment via a failure above the liquid level at less than 0.345 MPag are

5E-5 and 0.8 (subsection 3.2.2.3.2). The initial respirable source term is:

1000 g * 1.0 * 5E-5 * 0.8 = 4E-2 g

This source term is generated within glovebox confinement.

7.3.3.3

Residue Dissolution Example Assessment

See oxide dissolution example assessment in subsection 7.3.2.3.

7.3.4 Metal Dissolution

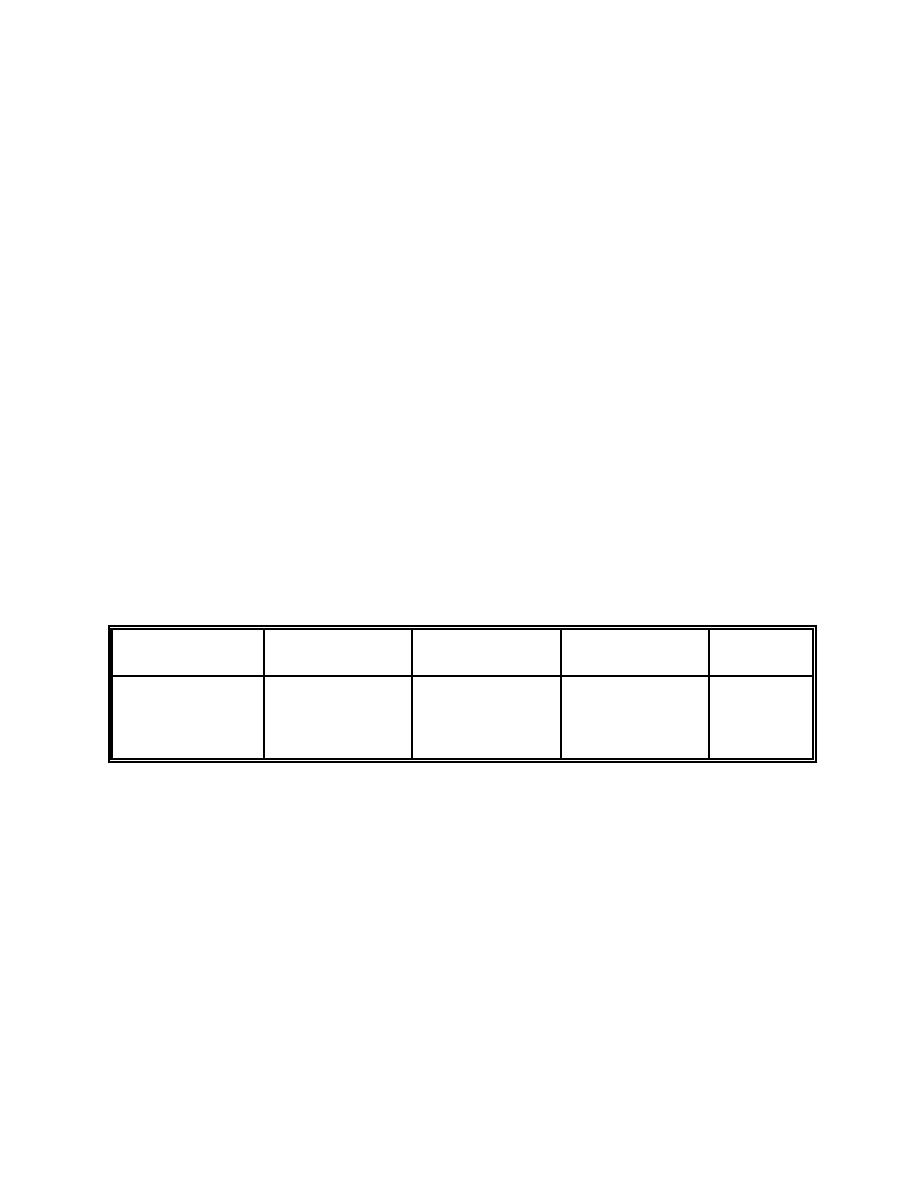

Release topics explored in this example are listed in Table 7-7.

Table 7-7. Metal Dissolution Example Topics

Liquid

Metal

Powder

Surface

Criticality

- Explosion shock

- Explosion shock

- Energetic

- None

- None

effect

effects

oxidation reaction

- Venting of

pressurized liquids

7.3.4.1

Hazard Summary

Recycle metal is brought into the recovery facility in a ready-to-dissolve form after receipt in

the adjoining Plutonium Vault Facility. The inner can containing the metal is brought into

the glovebox via an airlock. The metal is removed and placed in a small spray chamber sitting

on top of a slab vessel similar to the oxide and residue dissolvers. First, 14% by weight

sulfamic acid is added to the slab vessel from a dedicated feed tank. It is circulated through

the spray chamber via a small centrifugal pump to dissolve the metal and generate a plutonium

solution. Process and instrument air and nitrogen are fed into the glovebox by pressurized

sources ranging from 0.1 to 0.45 MPag (15 to 65 psig). A heat exchanger using 0.21 MPag

steam (35 psig) is used to heat the circulating acid. When the process is complete and the

circulating plutonium solution is diverted to the accountability slab tank, 4% nitric

Page 7-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |