|

|||

|

|

|||

|

Page Title:

Oxidation at Elevated Temperatures Below Ignition Temperature |

|

||

| ||||||||||

|

|  DOE-HDBK-3010-94

4.0 Solids; Metals

4.2.1.1.2 O xid ation at E levated T em p eratu res B elow I gn ition T em p eratu re.

Stewart (1963) reported on oxides from heating small pieces (less than 13 g) of unalloyed and

delta-alloy plutonium metal to various temperatures in various atmospheres. Two shapes

were used: billets (cylinder 0.7 cm diameter by 1.0 cm long) and swarf (turnings). Various

experimental configurations were needed for different experimental conditions. The pertinent

data are tabulated in Table 4-1 with source data from the referenced document reproduced in

Tables A.28, A.29a, A.29b, and A.30 in Appendix A. The size distributions of airborne

materials are shown in Figures A.23 and A.24 in Appendix A.

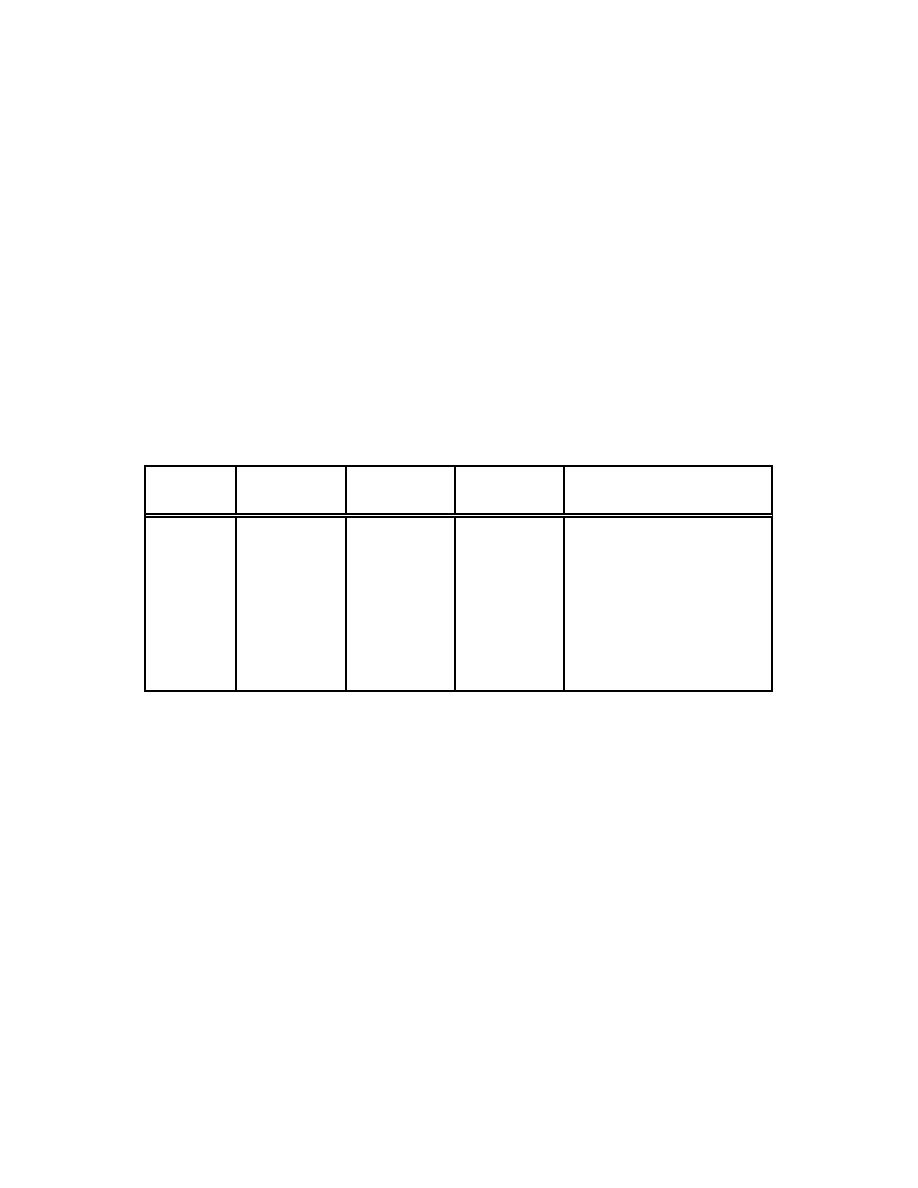

Table 4-1. M easured ARFs During Oxidation of Unalloyed and

Delta-Phase Plutonium at Elevated Tem peratures in Air

(Tables 3, 5 and 7 - Stewart 1963)

M etal

M ass

Hum idity

Tem perature

m g H2O/l air

ARF

Phase

Specim en (g)

123 oC

delta

7.483

0.03

1.5E-3

(0.033 oxidized)

113 oC

delta

7.344

1.50

3.2E-5

(0.054 oxidized)

123 oC

delta

8.602

16.0

4.8E-6

(0.035 oxidized)

beta

11.021

0.03

1.4E-6

(0.57 oxidized)

beta

10.802

8.0

1.1E-6

(1.0 oxidized)

beta

7.191

8.0

3.3E-6

(0.76 oxidized)

113 oC

alpha

9.397

16.0

1.3E-6

(0.21 oxidized)

123 oC

beta

11.265

16.0

5.6E-7

(0.17 oxidized)

beta

8.154

16.0

1.0E-6

(0.65 oxidized)

*

Mass Median Diameter in m Aerodynamic Equivalent Diameter.

At temperatures below the ignition temperature (experiments performed at 113 and 123 oC),

the unalloyed and alloyed metal behave differently. The oxidation rate for the delta-phase

alloy is stepwise and two orders of magnitude less than for the unalloyed metal. The

difference is attributed to the formation of a protective oxide film (the crystalline matrix

spacing for delta-phase metal and the dioxide are very similar and the dioxide adheres to the

metal surface). The film must crack and fall away before additional oxidation can occur.

The particle size distribution of the bulk oxide generated is very wide (0.1 to 300 m Dg).

The oxidation and release rate experimentally observed were continuous during the oxidation

of unalloyed metal. Except for a single anomalous high release value measured for delta-

phase metal at 123 oC in low humidity air with a very low fraction oxidized (1.5E-3), the

ARFs for both types of metal phases are bounded by a release of 3E-5 (also very low

fraction oxidized) and ranging to a value of 6E-7. The measured size distribution as

Page 4-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |