|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-HDBK-3010-94

7.0 Application Examples; Reduction Line Example

because it often becomes a mess in a hurry otherwise. Numerous oil stains are

visible on the calciner insulation. Extensive accumulations of tape are visible at

several connection points on the hydraulic lines. A number of outstanding work

requests exist on the unit.

3. The paint on combustible hydrofluorinator shielding is thin and obviously worn

with numerous scratches and chips revealing the underlying material.

Such findings indicate that the integration of operations, maintenance, assessment, etc.,

functions is poor. The proper emphasis and support is not being given to safety management

programs regardless of how much effort is being expended on "safety analysis." On the

other hand, opposite findings would indicate that actual issues are being systematically

addressed in an effective manner. Such considerations are real, directly relevant to the

overall facility safety basis, and not amenable to effective assessment by source term

considerations alone.

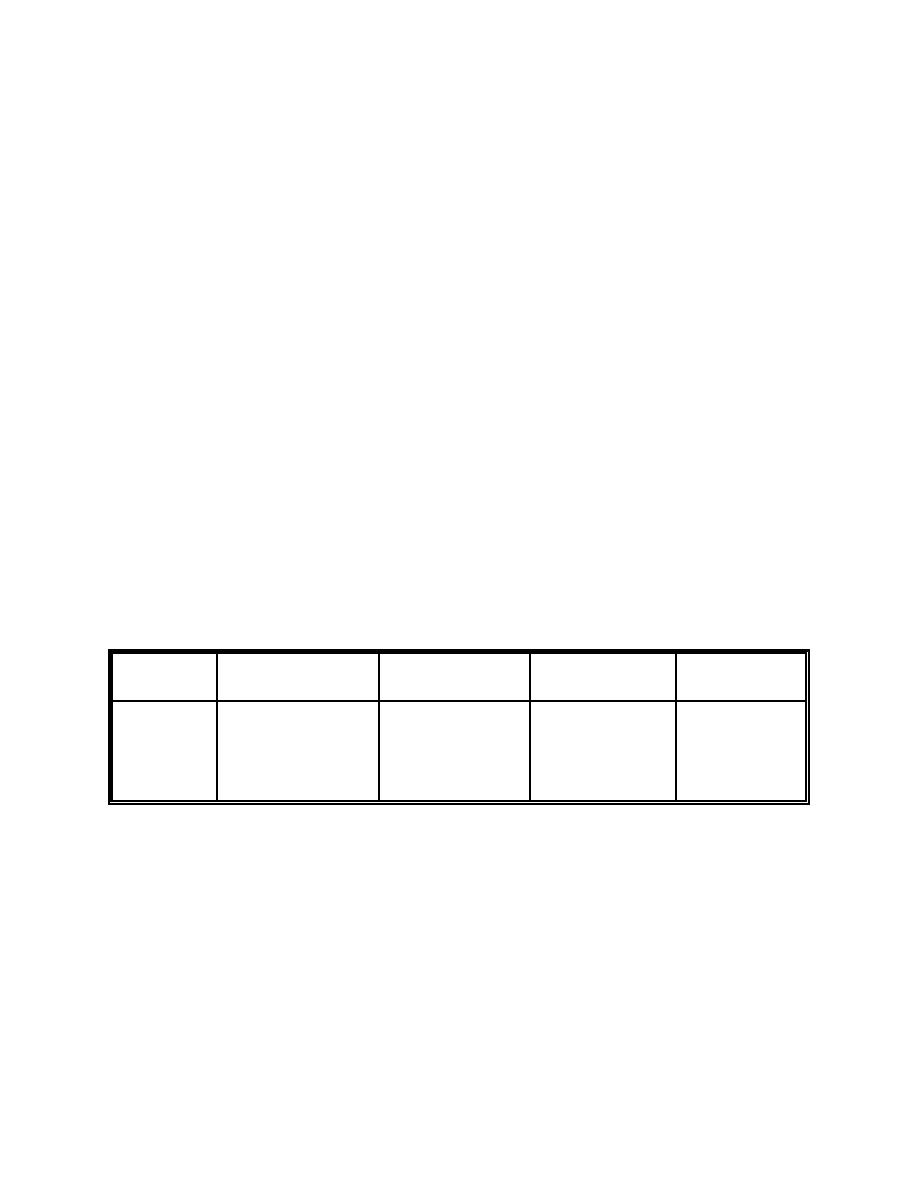

7.3.8 Reduction Line

Release topics explored in this example are listed in Table 7-11:

Table 7-11. Reduction Line Example Topics

Liquid

Metal

Powder

Surface

Criticality

- N/A

- Disturbed molten

- Thermal stress

- None

- None

metal surfaces

- Explosive shock

- Self-sustained

effects

oxidation

- Explosive blast

effects

7.3.8.1

Hazard Summary

Plutonium fluoride is received from the hydrofluorination glovebox. A plutonium fluoride

charge, an excess of calcium metal, and a pyrotechnic charge are mixed in a magnesium

oxide crucible. The crucible is placed in a metal reduction can, which is then sealed by

temperature until a thermite-type exothermic reaction is initiated between the plutonium

fluoride and calcium. At temperatures between 1500 oC and 1700 oC, and pressures between

0.34 and 2.8 MPag (50 to 400 psig), the mixture of reaction products is molten and the

Page 7-53

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |