|

|||

|

|

|||

|

Page Title:

Figure 5-3. The right mixture of air and gases in an enclosure can cause an explosion |

|

||

| ||||||||||

|

|  DOE-HDBK-1092-2004

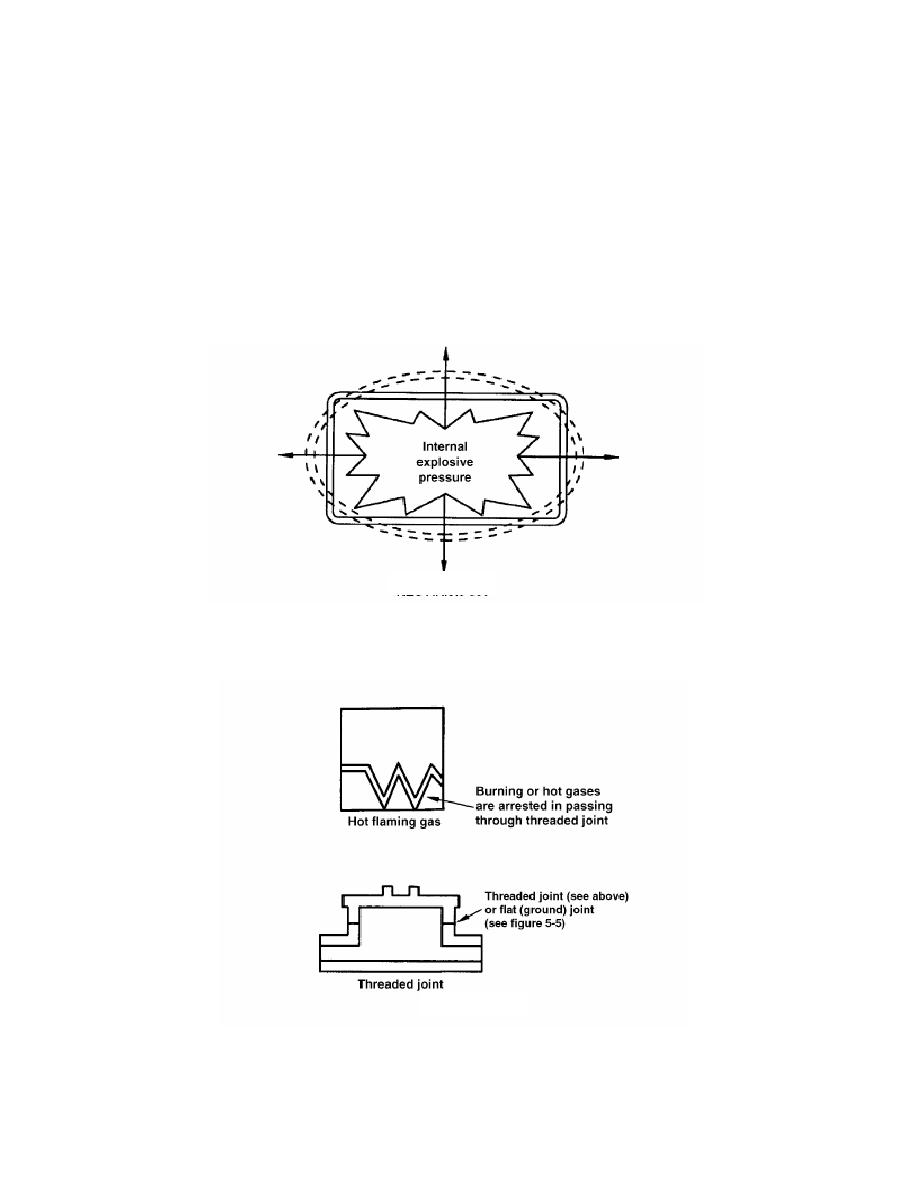

factor of 4 is used. That is, the enclosure shall withstand a hydrostatic pressure test of four

times the maximum pressure from an explosion within it.

In addition to being strong, the enclosure shall be flame-tight. This term does not imply that the

enclosure is hermetically sealed but rather that the joints cool the hot gases resulting from an

internal explosion so that by the time they reach the outside hazardous atmosphere, they are

too cool to affect ignition. The strains and stresses caused by internal explosive pressures are

illustrated in Figure 5-3 (dotted lines indicate the shape that a rectangular enclosure strives to

attain under these conditions). Openings in an enclosure strive to maintain the shape of the

enclosure. Openings in an explosion-proof enclosure can be threaded-joint type (Figure 5-4) or

flat-joint type (Figure 5-5).

Figure 5-3. The right mixture of air and gases in an enclosure can cause an explosion

that creates internal pressures that can rupture the enclosure if not released properly.

Figure 5-4. Threaded joints can be used as an escape path to cool the hot gases as

they pass through the threads to the outside of the enclosure.

5-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |