|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-HDBK-1092-98

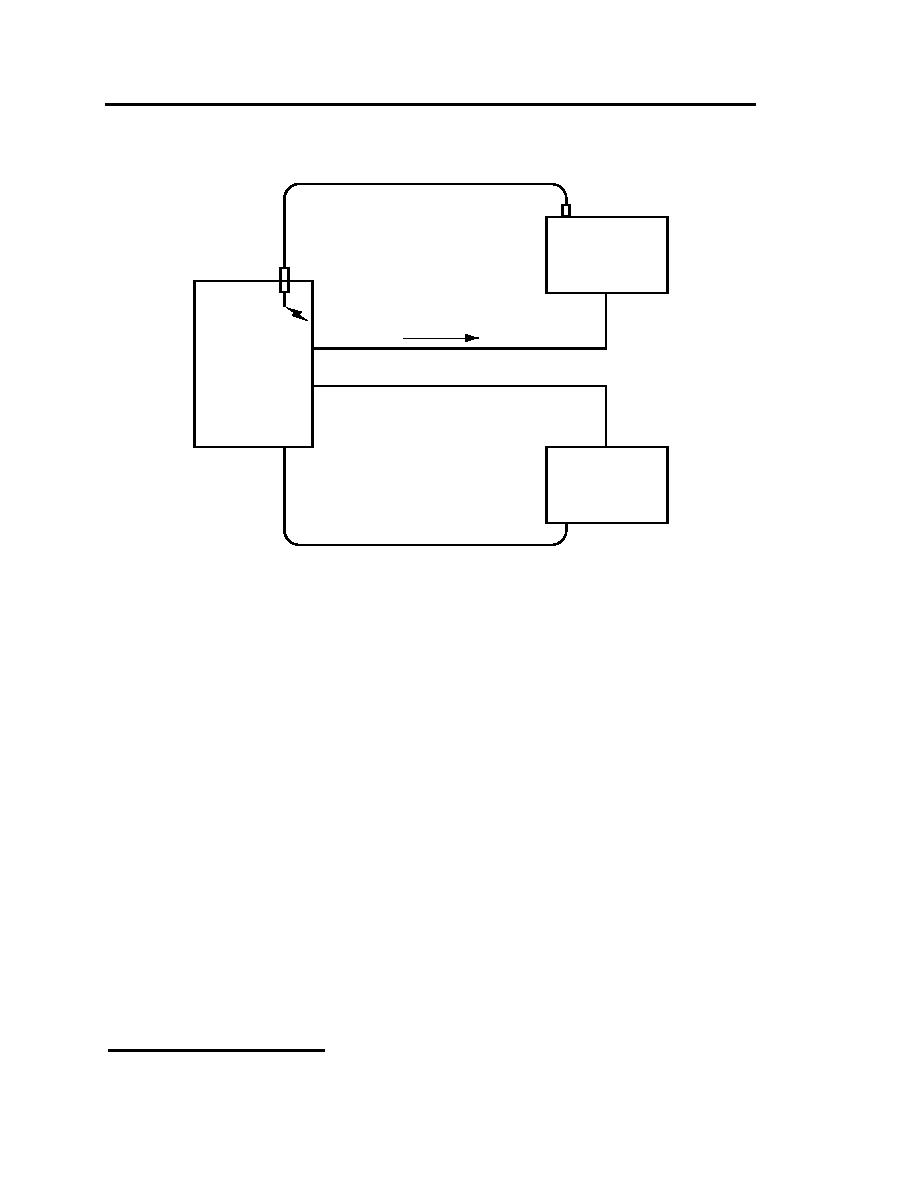

Process Power Cable

Process

Power

Supply

arc

I arc

Process Power Ground

Process Control Ground

Process

Enclosure

Process

Control

Control/Instrument Lines

CONDUCTIVE COUPLING SOLUTION

Figure 10-3. It has been possible to install a separate return conductor for the power supply. The arc currents

no longer appear in series with the process controls. There is no conductive coupling.

2. Capacitive Coupling. (High-impedance proximity coupling) The technique for increasing

resistance to capacitive coupling among cables is to ground one end of the shield to produce

the shortest, most direct shunt path back to the source of the coupled current as is shown in

Figures 10-4 and 10-5.

Caution: It is possible to inadvertently INCREASE coupling between source and load if the

shield ground does not properly shunt the current coupled onto the shield.

3. Inductive Coupling. (Near-field, low-impedance loop-to-loop coupling) The technique for

increasing resistance to magnetic coupling in shielded cables is to ground BOTH ends of the

shield to an effective signal return ground as is shown in Figures 10-6 and 10-7.

4. System Signal Returns. Each installation will require individual analysis and treatment. A

single ground poses no problem, but multiple grounds can result in a ground loop. These can

upset the proper functioning of instruments. A signal isolator offers a way of overcoming the

problem.

strategy (see Figure 10-8) makes use of a common signal ground as a reference for analog

1

The information in this section and figures 10-8 and 10-9 are reprinted with permission from the September

1991 issue of EC&M magazine copyright (c) 1991 Intertec Publishing Corporation. All rights reserved.

10-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |