|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-HDBK-1092-2004

6.5.4

CONDUIT

Because the vapors given off by a storage battery are very corrosive, the wiring shall withstand

the corrosive action, and special precautions are necessary as to the type of insulation used

and the protection of all metalwork. It is stated by their respective manufacturers that conduit

made of aluminum or silicon-bronze is well suited to withstand the corrosive effects of the

vapors in battery rooms. In contrast, if steel conduit is used, it is recommended that it be zinc-

coated and kept well painted with asphaltum paint.

6.5.5

BATTERY ROOM

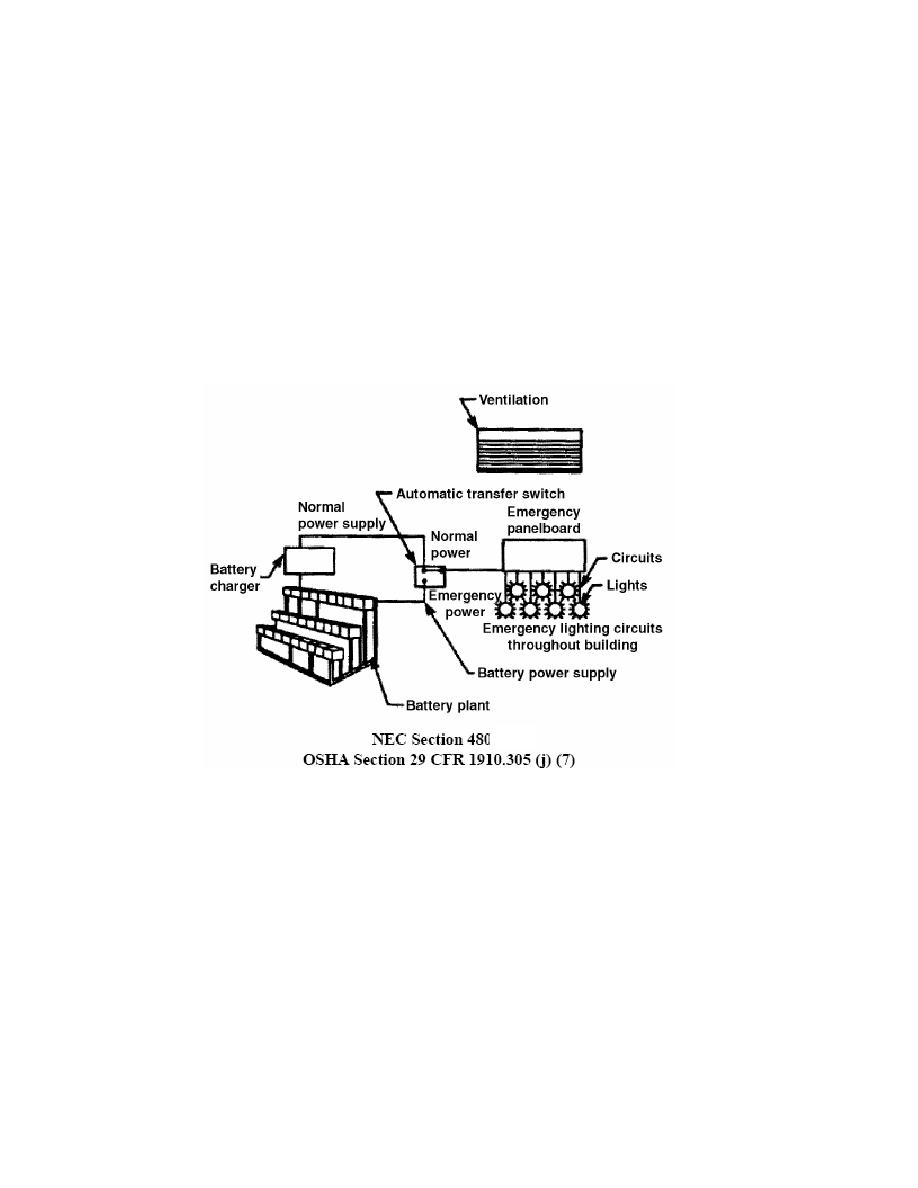

There are no special requirements for the type of fixtures or other electrical equipment used in

the battery room, with proper ventilation. (See NEC 480 and Figure 6-4)

Figure 6-4. With proper ventilation there are no special requirements for wiring and

equipment installed in battery rooms per NEC 480.

6.5.6

PERSONAL PROTECTIVE EQUIPMENT

PPE capable of protecting employees from acid splashes shall be used by those working on or

servicing batteries. The minimum acceptable PPE shall include acid-resistant gloves, aprons,

and chemical-splash goggles. A full-face shield may also be used; it shall not, however, be worn

in place of goggles. The design and use of PPE for wear when servicing batteries shall comply

with OSHA requirements. Safety showers and eyewash stations are also required.

6.5.7

TOOLS

Tools used for working on batteries shall be insulated or nonsparking.

6-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |