|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOESTD107393

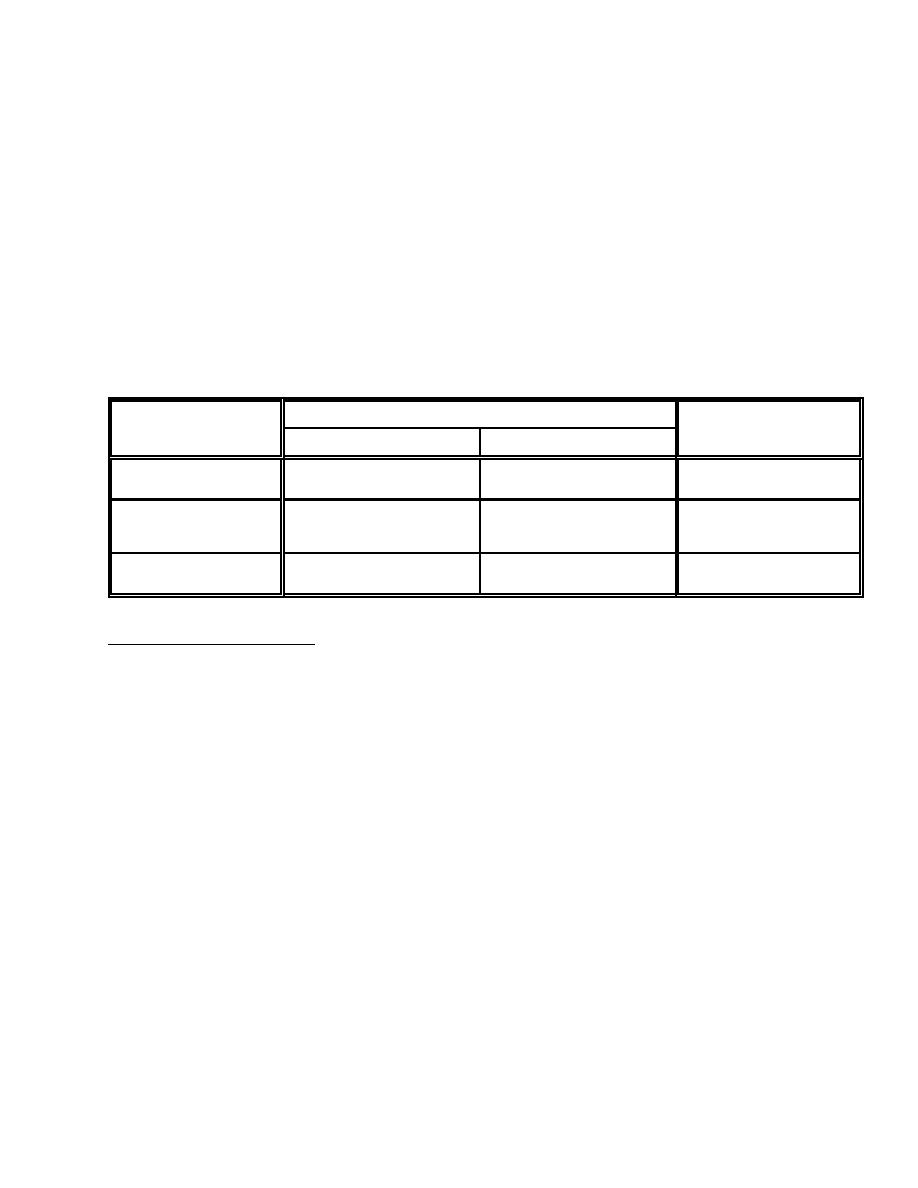

If desired, the categories of design requirements can be subdivided. For example, within the safety

design requirements, subsets can be defined to cover hazards to off-site personnel, on-site personnel,

and facility workers. In such a subcategorization, protection of off-site personnel would correspond to

Safety Class 1 as defined in DOE 6430.1A; the environmental design requirements, with the terms

"high hazard," "moderate hazard," and "low hazard" as defined in DOE 5481.1B; and mission design

requirements, with the DOE 5000.3B definitions of operational delays or interruptions that are

reportable. When the design requirements categories are subcategorized, correlations with existing

graded approaches become more obvious. Such subcategorizations might be advantageous when

phasing program implementation. For example, the protection of off-site personnel could be

emphasized during the first phase, with other levels of protection being developed in subsequent

phases. The following matrix shows how safety and environmental design requirements can be

subcategorized and correlated with each other. For example, the abbreviation SC-2 indicates Safety

Class 2.

PERSONNEL PROTECTION

ENVIRONMENTAL

SUBCATEGORY

PROTECTION

Nuclear Hazards

Other Hazards

SC-1

OFF-SITE Significant

OFF-SITE Significant

N/A

Consequences

Consequences

SC-2

ON-SITE Significant

ON-SITE Significant

OFF-SITE

Consequences

Consequences

Irreversible

Consequences

SC-3

LOCALIZED

LOCALIZED

ON-SITE Irreversible

Consequences

Consequences

Consequences

Composite Facility/SSC Grades. Many QA programs now have different quality levels that can be used

to differentiate work activities in terms of the importance of the equipment involved. However, there is

only a limited number of quality levels--at some facilities, only two; at others, three. Typically, quality

level I is applied to safety equipment; quality level II, to other important equipment, such as

environmental protection equipment; and quality level III, to the remaining equipment. It is difficult to

establish more than three different quality levels for application to activities such as maintenance or

testing. The numerous grades of more complex grading systems ultimately need to be reduced to a

small number of quality levels for practical application. Integrated, fairly simple grading systems are

essential.

The following matrix illustrates an example of composite consideration of facility grading and SSC

grading and how quality levels can be assigned to various grades of SSCs at facilities of various

importance levels. The purpose of this matrix is to show how the highest level of quality (QLI) should

apply to the most important SSCs at the most important facilities. The lowest level of quality (QLIII)

should apply to the least important SSCs at the least important facilities. In the middle, medially

important SSCs at medially important facilities receive the middle level of quality assurance actions

(QLII). This table illustrates one method for achieving the general goal of applying the greatest

resources to the most important SSCs and the least resources to the least important SSCs.

I-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |