|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-STD-1112-98

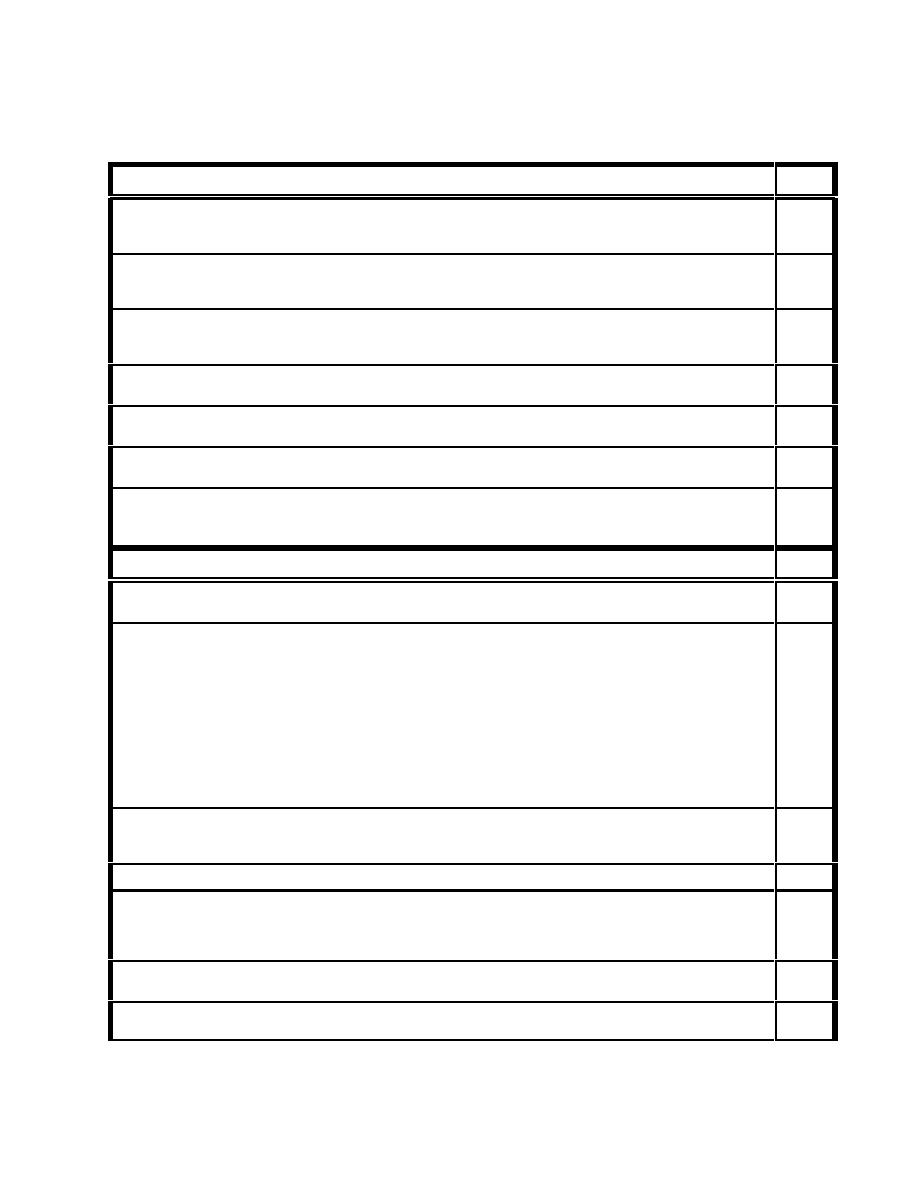

CHECKLIST FOR DOELAP SERVICE LABORATORY INDEPENDENT ASSESSMENTS

Accept

EQUIPMENT AND FACILITIES

1. A list and description of the facilities and measuring equipment used in all the systems and protocols for which accreditation is

requested is available in the facility. The list allows measurement systems with maintenance logs to be correlated with

calibration records.

2. Procedures are established for replacing or bringing spare equipment into routine service, repairing equipment on a rapid-

response basis and/or using the services of another DOELAP-accredited laboratory to ensure continuity of service when systems

or personnel fail to perform as required.

3. Adequate procedures and/or quality controls are in place to ensure the performance of measurement equipment to the levels of

precision and accuracy defined by the laboratory for each measurement protocol. The procedures to be implemented when the

equipment fails to meet these criteria are documented.

4. To help in evaluating the stability of equipment performance, records of preventive maintenance and repair activities are

available for each piece of critical measurement equipment.

5. Continuity of equipment operation is adequately provided for through service contracts or through an in-house capability to

maintain equipment and stock parts.

6. Relevant environmental parameters in the counting facility, such as counting room background measurements, are measured and

recorded.

7. The calibration of equipment is verified at regular intervals determined by equipment type, manufacturing specifications,

accumulated stability data, or some other reasonable plan to demonstrate the reliability of the measurements performed by the

processor.

Accept

CALIBRATION

1. Calibration and verification practices for measurement equipment or systems are described in a procedure(s). The procedure(s)

identifies the calibration services, reference materials, calibration intervals, and measurement assurance programs used.

2. Calibration and verification records for major equipment used in radiobioassay analyses include the following:

equipment name or description

____

manufacturers name

____

model, style, serial number, or other identifying mark

____

identification of all equipment variables requiring calibration or verification

____

range of energy and nuclides (or concentrations) used for calibration

____

allowable error (taking into consideration instrument tolerance) to coincide with the requirements of each protocol

____

date and result of last calibration/verification, including assessed uncertainty of measurement

____

identification of staff member or position responsible for equipment calibration, or of external service performing calibrations

____

identity of reference standard and how the individual radiobioassay calibration data relate to national standards or nationally

accepted measurement systems

____

3. Radionuclide standards or calibration phantoms used for equipment calibrations and to test the accuracy of analytical procedures

and/or measurement equipment are designated as Standard Reference Material (SRM) by NIST, Transfer Reference Standards

(TRS), or standards directly compared with an appropriate SRM. Care is taken to maintain a standard source geometry.

4. Calibration procedures used are appropriate for the radionuclides of interest.

5. Calibrations of direct radiobioassay measurement systems are performed with known sources of radionuclides incorporated in a

suitable simulation of the body or the body part of interest, or with techniques that are technically equivalent. These calibration

phantoms should have radioactivity incorporated uniformly throughout the organ of interest or the simulated body. Calibration

phantoms should be anthropomorphic representations of appropriate geometries of the body whenever feasible.

6. For each measurement system, a calibration is performed for the specific geometry and radionuclide or energy range for which

accreditation is requested.

7. The Laboratory strives to maintain system performance (check source measurements) within the range of 10% at the 95%

Confidence Level (1.96 s ) of the established value for the check source.

A-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |