|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-STD-1112-98

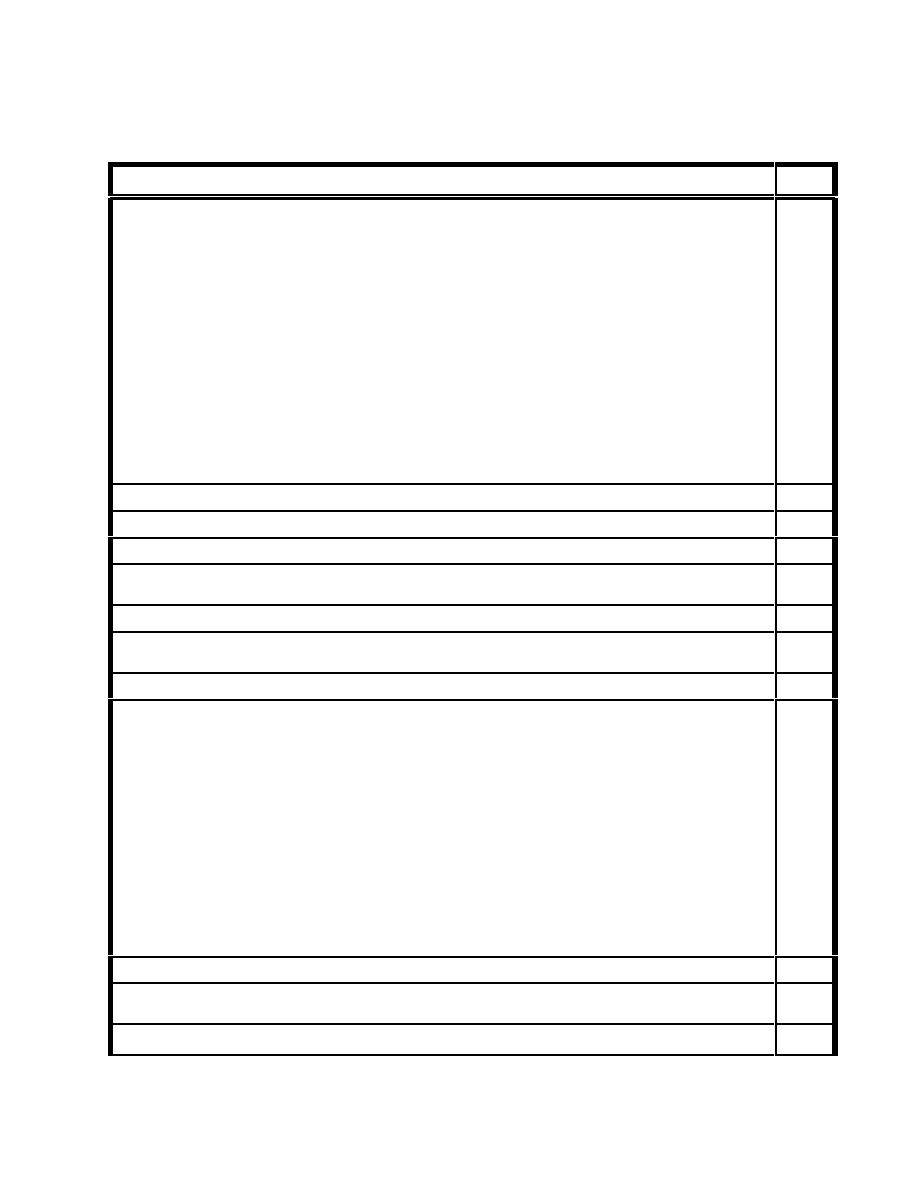

CHECKLIST FOR DOELAP SERVICE LABORATORY INDEPENDENT ASSESSMENTS

Accept

QUALITY ASSURANCE

1. A documented, approved quality assurance (QA) plan is in place, and addresses the following aspects of quality assurance:

organizational structure, management and operational responsibilities

____

instructions and procedures, including procedure validation

____

qualification and training of laboratory personnel

____

document control

____

procurement of materials

____

identification and control of material and samples (chain of custody)

____

inspection and testing of material and equipment

____

control and maintenance of calibration standards

____

corrective actions

____

review of procedures, specifications, and operating logs

____

observation of operations and evaluation of quality control data

____

quality assurance records

____

documentation of detector capabilities, detector background checks, relative bias, relative precision, and methods of

calculating results for periodic quality control determinations

____

records management including any deviation from the use of established procedures, equipment, or facilities

____

verification, validation, and documentation of computer software used for calculations

____

documentation of specific customer requirements.

____

2. Internal QA assessments on the use of written procedures are performed at least annually.

3. Procedures are reviewed at least once every two years.

4. The QA plan includes practices for ensuring staff competency.

5. The QA plan describes the training program used to prepare staff to conduct assigned tasks (procedures), and for retraining staff

when assignments or procedures are revised.

6. Equipment used to process biological samples is procured and used in conformance with the QA plan.

7. Results of the laboratory's participation in intercomparison programs or internal measurement assurance programs are consistent

with requirements defined in the QA plan.

8. Open lines of communication are maintained between technical and supervisory staff.

9. Quality control protocols for measurement systems are in place and include:

use of traceable radionuclide reference standards

____

performance checks of measurement systems

____

instrument calibration

____

intra laboratory analyses (e.g., known quantities, replicates, and blanks)

____

participation in available inter-laboratory intercomparison comparison programs

____

computational checks

____

review of procedures, specifications, and operating logs

____

observation of operations and evaluation of quality control data

____

evaluating conformance to the performance criteria of ANSI N13.30

____

evaluating conformance with internal performance criteria set by the QA plan

____

evaluating quality control data to ensure the long-term consistency of analytical results

____

verification of Lc, MDA, and/or MDC determinations

____

background counts

____

blind samples

____

measurement equipment controls such as humidity, cooling, and power fluctuation, if necessary.

____

10. Laboratory staff are familiar with and implement the documented quality control program.

11. An authorized laboratory staff member examines all daily QC results on a periodic basis, and takes timely action to correct any

deficiencies before samples and sample residuals are discarded and results are reported.

12. Quality control results are summarized on a quarterly basis.

A-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |