|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|  DOE-STD-3014-96

Perforation Thickness. The perforation thickness (tp) is

6.3.2.1.2

defined as the panel thickness that is just great enough to

allow a missile to pass through the panel without any exit

velocity. The mean perforation thickness, tp (ft), for reinforced

concrete panels subjected to a cylindrical rigid

(nondeformable) steel missile impact, based on Reference 4,

is:

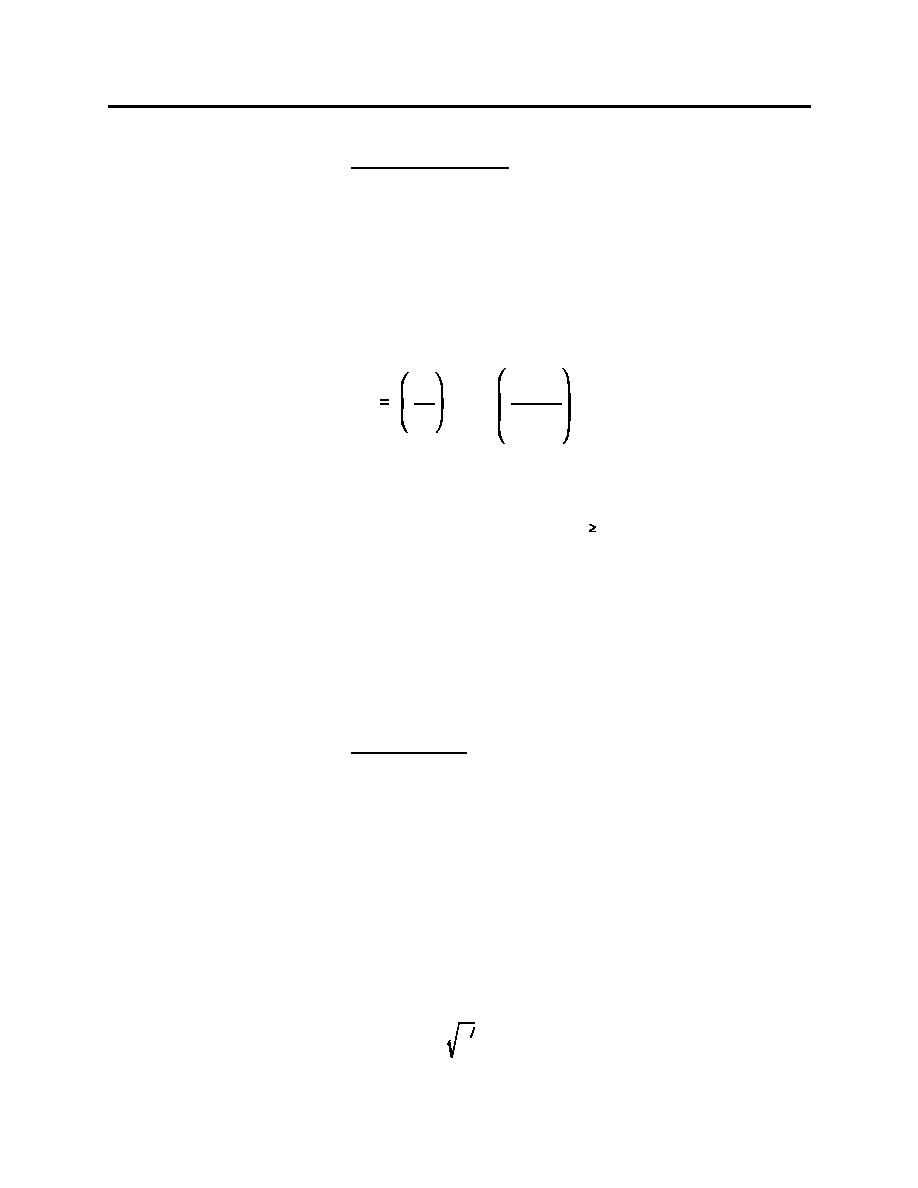

0.5

0.25

2

U

MV

tp

(6-2)

V

/

Dfc

The parameters U, V, M, D, and f/c are the same as those

defined in Equation 6-1. To prevent perforation, minimum

concrete thickness, td, should be

1.2 tp, where tp is given by

the above formula. Other formulas, as listed in Table I and

discussed in Appendix C, may also be used if applicable.

For further discussion and an example using these formulas,

refer to the technical support document for Chapter 6

(Reference 1).

6.3.2.1.3

Punching Shear. Missile impact on a concrete wall or slab

can induce shear failure, either near the periphery of the

impact area or at the edge of the wall or slab. The former is

called punching shear failure, and the latter is known as the

reaction shear failure. The following punching shear criterion

is applicable for this standard. For design against punching

shear, capacity is limited by the diagonal tension failure in the

concrete adjacent to the load. The ACI 318 and ACI 349

Codes (References 7 and 8) limit the punching shear stress

(psi) to

4 fc

68

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |