|

|||

|

|

|||

|

Page Title:

Table identifying required parts |

|

||

| ||||||||||

|

|  DOE-STD-1029-92

section is extremely important. For example, failure to specify a necessary item

could result in costly equipment downtime or using a substitute for a specialized

tool could damage equipment. It may be appropriate to provide some of this

information in tables. Lists of material may be more appropriately placed in an

appendix than in this subsection.

[2]

Identify certified or qualified parts and equipment needed for the activities.

[3]

Provide guidelines for selecting and assembling special tools, measuring and test

equipment, parts, and supplies.

[4]

Provide separate action steps for the different categories such as parts, supplies, or

measuring and test equipment.

[5]

Specify alternative tools and equipment if applicable.

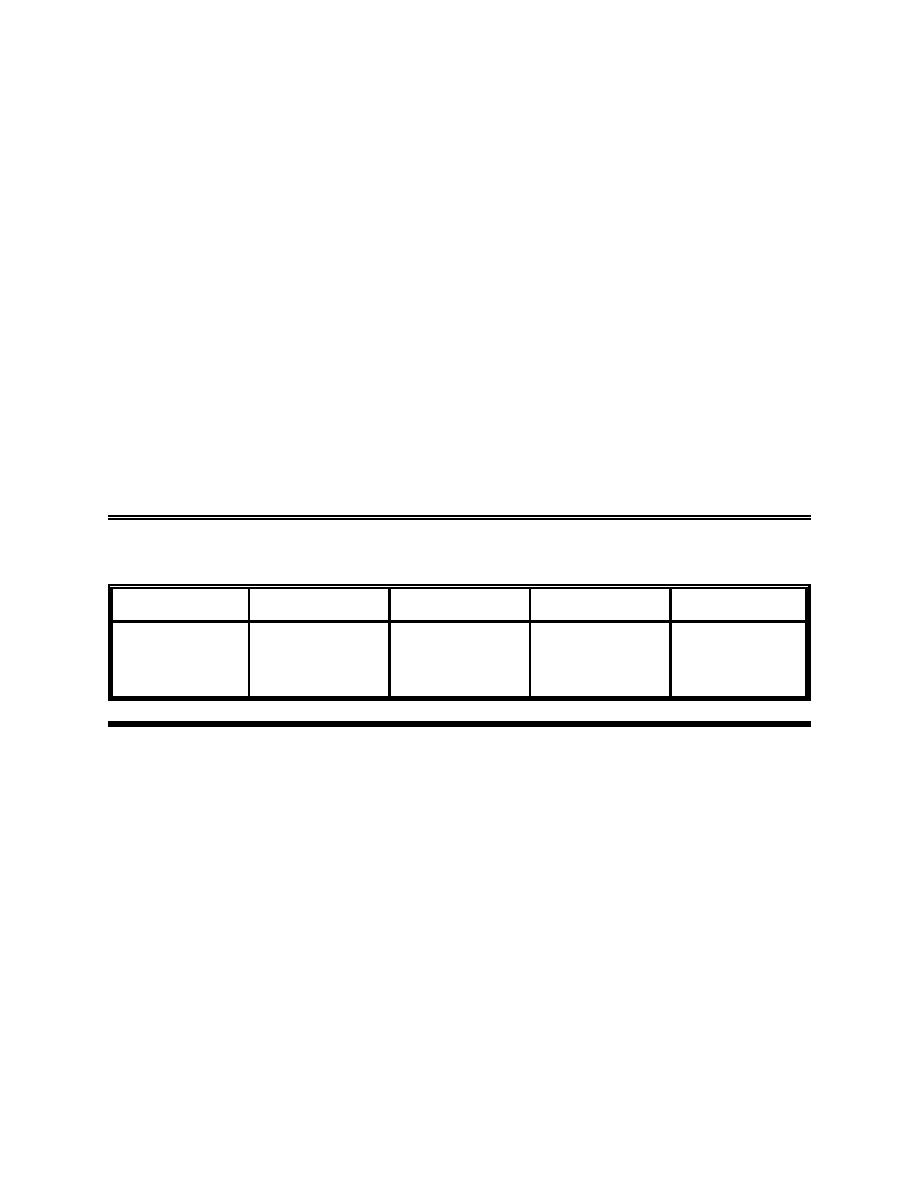

EXAMPLE 3-15. Table identifying required parts.

[3]

Obtain the following parts:

Description

Part Number

TIIC No.

Quantity

Class

Gasket

3

XX-XX-XX

1

EQ

Piston

5

YY-YY-YY

1

EQ

Nut

6

ZZ-ZZ-ZZ

2

NA

[6]

Identify specific equipment necessary to perform a procedure.

[7]

Avoid using the statement "or equivalent" when specifying equipment.

[8]

Do not specify ordinary craft tools such as standard pliers and wrenches.

[9]

If the procedure has a generic application, do not include instrument-specific

information such as serial number or calibration date. This information is included

in application-specific procedures.

[10]

Provide clear specifications for verifying the adequacy of test equipment.

Specifications include ranges, accuracies, and compliance with calibration

standards.

28

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |